9 Simple Techniques For Insulated Metal Spandrel Panels

Table of ContentsMore About Kawneer Spandrel Panel Metal SpandrelCurtain Wall Spandrel Panel Detail Fundamentals ExplainedExcitement About Insulated Spandrel Panel Detail

For unitised curtain walling, about 30% of the work being done on site, while 70% is performed in the factory. insulated spandrel panel. The total assembly of the systems in the factory brings a variety of benefits, which are: Enhanced quality control Concurrent manufacture and site preparation units can be put together while the structural frame is being constructed.This is ideal for high towers or constructing sites where there is a tight footprint Less space is required on site for layout is the another benefit Another advantage of unitised systems is that, unlike stick systems, they do not move effect sounds from flooring to flooring or horizontally from room to space.

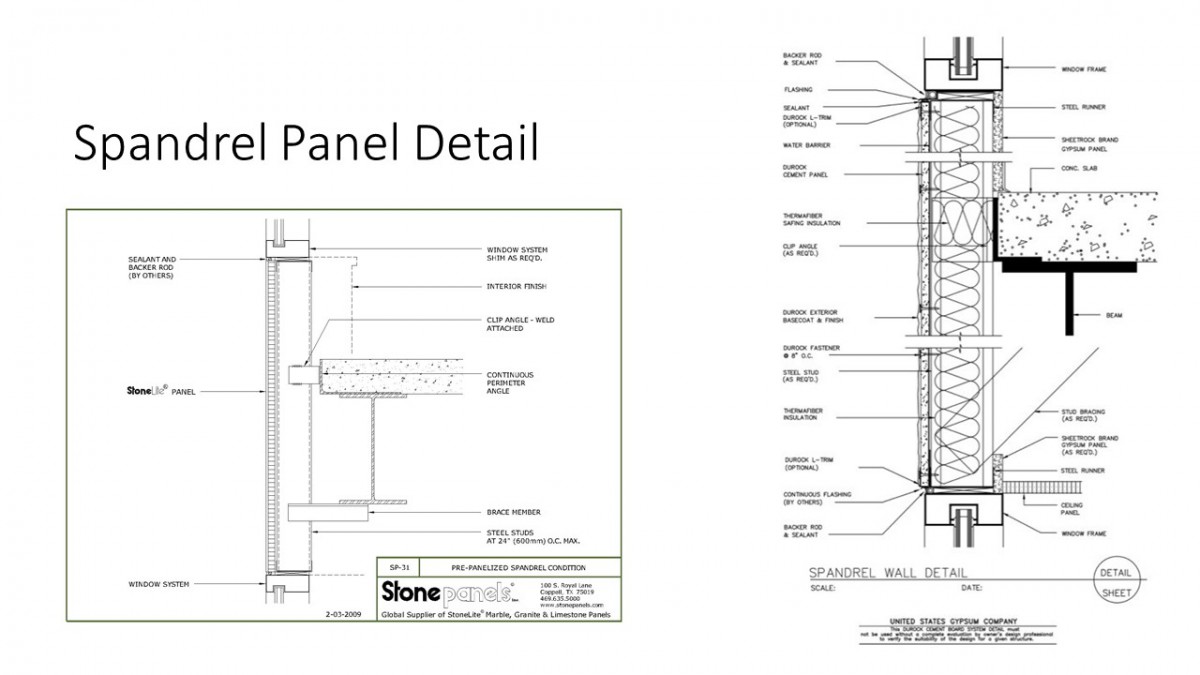

Sun-screening systems, spandrel panels and other infill panels can also be consisted of (kawneer spandrel panel metal spandrel). Aluminium is typically used for faade frames due to the fact that of its strength and stability. It is likewise highly resilient, moisture and corrosion-resistant and 100% recyclable. Mullions in a unitised system tend to be slightly larger, since they use to have an open area, compared to the tube-shaped mullions used in a basic stick system.

Modular glazing, which holds the glass using picture-frame-effect glazing beads Structural sealed glazing, where the glass is structurally bonded, giving a continuous glazed look to the faade Various levels of thermal performance are used, from standard to high insulation choices. All variations are thermally broken, however in high thermal insulation alternatives the extra performance can be attained by placing fiberglass enhanced polyamide strips in a skeleton structure to create multiple chambers.

Excitement About Gable Spandrel Panel

g. a range of requirements can be used in the Middle East including European and American standards depending on the nation dynamics and weather conditions. The air tightness test measures the volume of air that would travel through a closed window at a specific atmospheric pressure. The peak test pressure is figured out by the specifier based upon among the classes in BS EN 12152: 2002 curtain walling, air permeability, efficiency requirements and classification.

A greater test pressure may be defined if a more airtight structure is needed. Water tightness screening involves using a consistent water spray at an increasing atmospheric pressure up until water permeates the window. The peak test pressure is identified by the specifier based upon one of the classes in BS EN 12154:2000 drape walling, water-tightness, efficiency requirements and classification.

For instance, in a seaside official site area, they may wish to evaluate to a higher peak pressure. The wind load resistance is a procedure of the profile's structural strength and is tested by applying increasing levels of air pressure to simulate the wind force. The performance requirements with regards to wind resistance of curtain walling are listed in BS EN 13116:2001 curtain walling, resistance to wind load. When glass is used as the curtain wall, an advantage is that natural light can penetrate deeper within the building. The curtain wall faade does not bring any structural load from the building aside from its own dead load weight. The wall transfers lateral wind loads that are event upon it to the main building structure through connections at floorings or columns of the structure.

Curtain wall systems are typically developed with extruded aluminum framing members, although the very first curtain walls were made with steel frames (fire rated spandrel panel). The aluminum frame is generally infilled with glass, which supplies an architecturally pleasing structure, in addition to benefits such as daylighting. However, the results of light on visual comfort as well as solar heat gain in a building are harder to control when utilizing big amounts of glass infill.

Roof Spandrel Panels for Dummies

Curtain walls vary from store systems because they are designed to span several floors, taking into consideration style requirements such as: thermal expansion and contraction; building sway and motion; water diversion; and thermal performance for cost-efficient heating, cooling, and lighting in the building. 16 Cook Street, Liverpool, England, 1866.

Oriel Chambers, Liverpool, England,1864. What appears to be an early curtain wall, part of the Curtea Veche Palace in Bucharest, built in 1716 Buildings have actually long been constructed with the exterior walls of the building supporting the load of the entire structure. The development and widespread usage of structural steel and later reinforced concrete allowed fairly little columns to support large loads; thus, outside walls of buildings were no longer required for structural support.

This paved the way to increased use of glass as an outside faade, and the modern-day curtain wall was born. Early prototype variations of drape walls might have existed in structures of wood building and construction prior to the 19th century, should columns have been utilized to support the structure instead of the walls themselves, particularly when large panels of glass infill were involved.